It’s no secret that the digital industry is booming. From exciting startups to global brands, companies are reaching out to digital agencies, responding to the new possibilities available.

09

Aug 2022

Agitated Thin Film Evaporator for Cardanol recovery

Cardanol is the main component of cashew nutshell liquid (CNSL), a byproduct of cashew nut processing. This nutshell liquid contains mainly anacardic acid and a smaller amount of cardol and its methyl derivatives. CNSL can be decarboxylated and distilled to yield high purity cardanol, a highly desirable alkylphenolic compound in the chemical industry. Cardanol finds use in the chemical industry in resins, coatings, frictional materials, and surfactants used as pigment dispersants for water-based inks. With the increased desire in the chemical industry to replace petroleum-based materials and move away from toxic substances, cardanol end-uses continue to expand as a diluent and intermediate for various derivatives and applications.

Cashew nutshell

Batch kettle distillation is commonly used as industrial method to evaporate Cardanol from CSNL. However, batch process has inherent disadvantage of long distillation time. Cardinol is heat sensitive product. Long distillation hours at high temperature catches color in Cardinol. This reduces the Cardinol quality and subsequent reduction in market value. Longer distillation hours can reduce Cardinol yield to 50-60%.

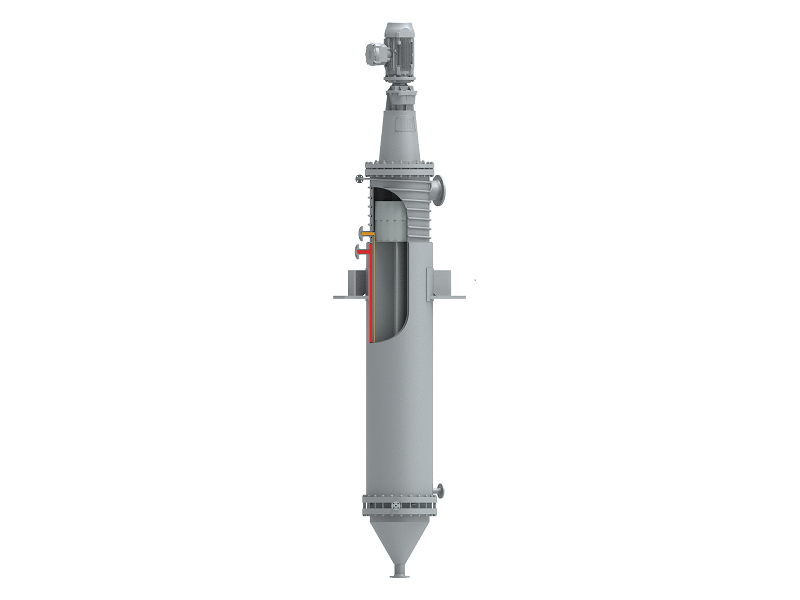

Considering heat sensitive properties of cardanol, its recovery and color can be improved if contact time to heating surface is reduced. Agitated Thin Film Evaporator (ATFE) is best fit for this requirement.

In ATFE, a thin film is formed on inside diameter of shell which is intensely agitated by rotor. The small holdup in the film reduces residence time to a few seconds. The turbulent flow within this thin film narrows the spread in residence time distribution. Required evaporation is achieved in a single pass, avoiding recirculation and repeated exposure of the product to the heated surface. These features provide big benefits while processing heat sensitive products. Also, ATFE can operate at high vacuum [maximum 1 mbar] to keep process temperature low. The product can be distilled with the help of hot oil/Steam heating on the jacket side. The product vapors flow counter currently to the feed and condense in a suitable cooling water condenser. The concentrate from ATFE and distillate from the condenser will be discharged continuously by pump.

Benefits of using ATFE for Cardanol evaporation

Improved evaporated Cardanol colour as compared to batch kettle.

Increased rate of cardinol recovery to 80% and more, due to high rates of heat transfer achieved in ATFE combined with low residence time and high vacuum which limits polymerization.

Better handling of the highly viscous and tarry residue with ATFE rigid rotor design which add value to the customer as the un-polymerised residue is a suitable by- product.

Technoforce has already designed and built more than 300 Agitated Thin Film Evaporators for various industrial sectors. We offer evaporation technologies like Agitated Thin Film Evaporation, Short Path Distillation and Drying, Falling Film, Rising Film and Forced Circulation Evaporation, as well as Liquid-Liquid Extraction and Crystallization technologies.

Technoforce is ISO 14001:2015, ISO 45001:2018, ISO 9001:2015 certified company with 2 decades of experience in construction under ASME U stamp and PED/CE mark certification. Technoforce also have Pilot Plants facility in The Netherland and India, sales office in Germany. For more details, visit Technoforce website www.technoforce.net.